How to determine the performance limit of a microcontroller?

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

Determining the performance limit of a microcontroller (MCU) is crucial for ensuring it meets the requirements of a robot motion control system. Here are the key factors and methods to evaluate an MCU's performance limits:

1. Key Performance Metrics

1.1 Clock Speed (MHz/GHz)

-

Definition: The number of cycles the MCU can execute per second.

-

Impact: Higher clock speeds generally mean faster execution but also higher power consumption.

-

Limitation: Not all instructions take 1 cycle; check the CPI (Clocks Per Instruction).

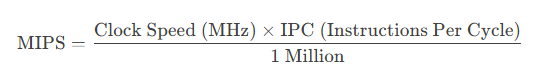

1.2 MIPS (Million Instructions Per Second)

-

Formula:

- Example:

-

ARM Cortex-M4 @ 100 MHz ≈ 125 MIPS (1.25 DMIPS/MHz × 100 MHz)

-

Cortex-M7 @ 216 MHz ≈ 462 MIPS (2.14 DMIPS/MHz × 216 MHz)

-

1.3 DMIPS (Dhrystone MIPS)

-

A standardized benchmark for comparing CPU performance.

-

Reference:

-

Cortex-M0: 0.9 DMIPS/MHz

-

Cortex-M4: 1.25 DMIPS/MHz

-

Cortex-M7: 2.14 DMIPS/MHz

-

1.4 FLOPS (Floating-Point Operations Per Second)

-

Critical for control algorithms (PID, kinematics, filtering).

-

Example:

-

Cortex-M4 (with FPU) ≈ 1.5 MFLOPS @ 100 MHz

-

Cortex-M7 (with FPU) ≈ 5+ MFLOPS @ 216 MHz

-

1.5 Memory Constraints

-

Flash/ROM: Code size limits (e.g., 512 KB vs. 2 MB).

-

RAM: Real-time data processing (e.g., 128 KB vs. 1 MB).

-

Cache: Cortex-M7 has instruction/data cache (faster execution).

1.6 Peripheral Throughput

-

PWM Resolution: 16-bit vs. 8-bit (affects motor control precision).

-

ADC Speed: 1 MSPS vs. 5 MSPS (for fast sensor feedback).

-

Communication Speed:

-

SPI (50 MHz vs. 100 MHz)

-

CAN FD (5 Mbps vs. classic 1 Mbps)

-

2. Methods to Determine Performance Limits

2.1 Benchmarking

-

Dhrystone: Measures integer performance (DMIPS).

-

CoreMark: More modern than Dhrystone, better for embedded systems.

-

Whetstone: Measures floating-point performance (FLOPS).

2.2 Real-World Testing

-

Control Loop Timing:

-

Measure the time to execute a PID loop (e.g., 10 µs @ 100 MHz).

-

Use an oscilloscope to check interrupt latency.

-

-

DMA vs. CPU Transfer:

-

Compare sensor data reading via polling vs. DMA.

-

2.3 Worst-Case Execution Time (WCET) Analysis

-

Static Analysis:

-

Disassemble code and count cycles for critical functions.

-

-

Dynamic Analysis:

-

Use a logic analyzer to measure execution time under stress.

-

2.4 Power vs. Performance Tradeoff

-

Dynamic Voltage & Frequency Scaling (DVFS):

-

Lower clock speed saves power but reduces MIPS.

-

-

Sleep Modes:

-

If the MCU sleeps between control cycles, check wake-up latency.

-

3. Performance Bottlenecks in Robotics

3.1 Motor Control Loop Frequency

-

Requirement:

-

Current Loop: 10–20 kHz (50–100 µs per cycle).

-

Position Loop: 100–500 Hz (2–10 ms per cycle).

-

-

MCU Limitation:

-

If an M4 @ 100 MHz takes 80 µs for PID, it can’t run at 20 kHz.

-

3.2 Sensor Fusion (IMU + Encoders)

-

Kalman Filter Computation:

-

A 6-state Kalman filter may take 200 µs on M4 but 50 µs on M7.

-

3.3 Communication Overhead

-

CAN Bus: 1 Mbps may limit real-time control in multi-axis robots.

-

SPI for Encoders: 10 MHz vs. 50 MHz affects response time.

4. Example: Cortex-M4 vs. M7 for Robotics

| Metric | Cortex-M4 (100 MHz) | Cortex-M7 (216 MHz) |

|---|---|---|

| DMIPS | 125 | 462 |

| FPU Speed | ~1.5 MFLOPS | ~5 MFLOPS |

| PID Loop Time | 80 µs | 20 µs |

| Max PWM Freq | 50 kHz (16-bit) | 100 kHz (16-bit) |

| Power (mA) | 30 mA (active) | 80 mA (active) |

Conclusion:

-

M4 is sufficient for simple robots (e.g., 2-DOF arms).

-

M7 is needed for high-speed control (e.g., drones, humanoids).

5. Tools for Performance Analysis

-

Keil MDK / IAR: Profiling tools to measure CPU load.

-

FreeRTOS Tracealyzer: Visualizes task execution timing.

-

Logic Analyzer (Saleae): Measures interrupt latency.

-

STM32CubeMonitor: Real-time power & performance tracking.

Final Recommendation

To determine if an MCU meets your robot’s needs:

-

Benchmark (CoreMark, Dhrystone).

-

Measure real-time control loop speed.

-

Check memory & peripheral bottlenecks.

-

Validate worst-case latency.

If the MCU can’t meet timing requirements, consider:

✔ Upgrading to a faster core (M7, dual-core)

✔ Offloading tasks to FPGA/CPLD

✔ Using DMA to reduce CPU load

Related Articles

- ·How do I secure an MCU from hacking or tampering?

- ·The best MCUs/MPUs for industrial humanoid robots

- ·Comparison of ARM vs. RISC-V MCUs

- ·ESP32 vs Arduino, Compare their differences and use cases

- ·The Application of Embedded Electronics in the Field of Consumer Electronics

- ·The application of embedded systems in the field of automotive electronics

- ·Make an MP3 player based on AVR microcontroller

- ·How many programming methods are there for the STM32G431RBT6 microcontroller?

- ·Design of solar automatic light tracking system