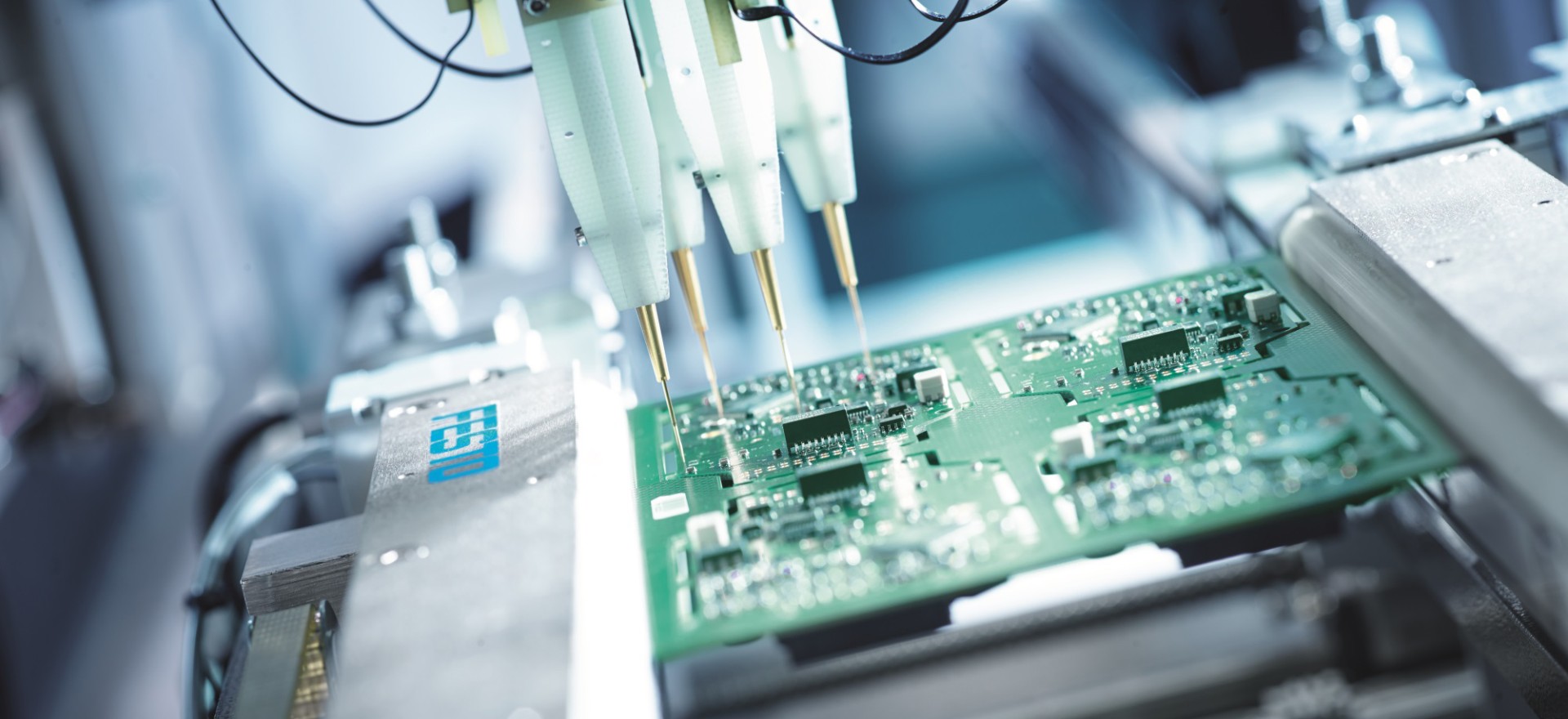

How to Create a PCB for STM32?

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

Creating a PCB for an STM32 microcontroller involves several steps, from schematic design to PCB layout and manufacturing. Below is a step-by-step guide to help you through the process:

Step 1: Select the STM32 Model

Choose the specific STM32 microcontroller (e.g., STM32F103C8T6, STM32F407VG) based on your project requirements (GPIO, ADC, PWM, communication interfaces, etc.).

Step 2: Design the Schematic

-

Use a PCB Design Tool:

-

KiCad (Free & Open Source)

-

Altium Designer (Paid, Professional)

-

Eagle (Free for small boards)

-

EasyEDA (Online, Easy to Use)

-

-

Add the STM32 to the Schematic:

-

Find or create the STM32 symbol in your tool’s library.

-

If not available, manually draw the symbol based on the datasheet.

-

-

Essential Components:

-

Power Supply:

-

3.3V regulator (e.g., AMS1117-3.3) if not using USB power.

-

Decoupling capacitors (100nF & 10µF near VDD/VSS pins).

-

-

Crystal Oscillator:

-

8MHz (HSE) for main clock + 32.768kHz (LSE) for RTC (optional).

-

Load capacitors (typically 20pF).

-

-

Reset Circuit:

-

A 10kΩ pull-up resistor + 100nF capacitor for debouncing.

-

-

Boot Mode Selection:

-

BOOT0 pin (10kΩ pull-down for normal operation).

-

-

Programming Interface:

-

SWD (SWDIO, SWCLK) for debugging/programming (STM32CubeProgrammer, ST-Link).

-

Optional UART (TX, RX) for serial bootloader.

-

-

LEDs & Buttons (for debugging).

-

-

Connect Peripherals (UART, SPI, I2C, GPIO, etc.).

Step 3: PCB Layout Design

-

Set Up Board Dimensions (based on enclosure or project needs).

-

Place Components:

-

Start with the STM32, then place power supply, crystals, and connectors.

-

Keep decoupling capacitors close to VDD pins.

-

Place the crystal near the MCU with short traces.

-

-

Route Traces:

-

Use 40-50 mil traces for power lines.

-

Use 8-12 mil traces for signals.

-

Avoid 90° angles (use 45° bends).

-

Keep high-speed signals (USB, SPI) short and away from noise sources.

-

-

Ground Plane:

-

Use a solid ground plane (improves noise immunity).

-

Avoid splitting the ground plane unnecessarily.

-

-

Silkscreen Labels:

-

Label pins, connectors, and test points for debugging.

-

Step 4: Design Rule Check (DRC)

-

Run DRC in your PCB tool to check for errors (unconnected nets, short circuits, etc.).

Step 5: Generate Gerber Files

-

Export Gerber files (for manufacturing) and drill files.

-

Common layers needed:

-

Top/Bottom Copper

-

Top/Bottom Silkscreen

-

Top/Bottom Solder Mask

-

Drill File (Excellon format)

-

Step 6: Order PCB Manufacturing

-

Use a PCB fabrication service like:

-

JLCPCB (Cheap & Reliable)

-

PCBWay

-

OSH Park (for small batches)

-

Upload Gerber files and select options (board thickness, color, etc.).

Step 7: Assemble the PCB

-

Solder Components:

-

Start with STM32 (use a soldering iron or hot air gun for QFP packages).

-

Solder passives (resistors, capacitors), then connectors.

-

-

Check for Shorts:

-

Use a multimeter to verify no shorts between power and ground.

-

Step 8: Program & Test

-

Connect Programmer (ST-Link, J-Link, or USB-UART for bootloader).

-

Upload Firmware:

-

Use STM32CubeIDE, Keil, or PlatformIO.

-

-

Debug:

-

Check power supply (3.3V).

-

Verify clock signals with an oscilloscope (if issues arise).

-

Additional Tips

-

Use Reference Designs: Check STM32 datasheets & evaluation board schematics (e.g., STM32 Nucleo boards).

-

Start with a Development Board: Prototype your circuit on an STM32 dev board before designing a custom PCB.

-

Add Test Points: Helps in debugging (e.g., for UART, SWD, power rails).

Related Articles

- ·Why can STM32 stand out from many 32-bit microcontrollers?

- ·How to distinguish fake chips?

- ·How do I secure an MCU from hacking or tampering?

- ·What are the advantages and disadvantages of using SoCs in embedded systems?

- ·How to implement a multi class neural network with STM32F103?

- ·Comparison of ARM vs. RISC-V MCUs

- ·How to achieve serial communication between STM32 and ESP8266?

- ·DS18B20 Temperature Sensor Detailed Explanation and Use Cases

- ·How to deploy artificial intelligence algorithms on STM32?

- ·The Difference Between 8-bit, 16-bit, 32-bit, And 64-bit Microcontrollers