Unveiling a Terminal Block's Connection

September 19 2023

Inquiry

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

QUICK RFQ

ADD TO RFQ LIST

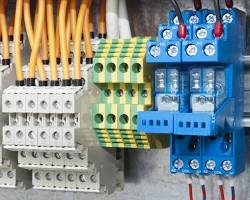

Terminal blocks serve as electrical connectors utilized for the purpose of connecting wires together. They offer a versatile and dependable means of wire connection, finding application in various scenarios such as electrical panels, control boxes, and machinery. Numerous types of terminal blocks exist, each possessing its own set of advantages and disadvantages. In this blog, we will discuss the different types of terminal blocks, how they work, how to wire a terminal block, and so on.

What is a terminal block?

A terminal block is a modular housing structure with an insulated body that connects two or more wires. Terminal blocks, also known as terminal connectors, connection terminals, or screw terminals, are employed in a variety of situations when it is necessary to connect electrical systems securely. They are perfect for designs that need for safe, orderly, and removable semi-permanent wire connections that can be quickly inspected or fixed in the field.

Types of terminal blocks

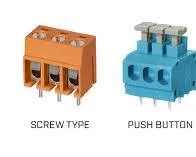

Some of the most common types of terminal blocks include:- Screw terminal blocks: The most popular kind of terminal block is a screw terminal block. They work with a range of wire sizes and are simple to use. However, if the wires are thick, they might be challenging to tighten and take a long time to connect.

- Push-in terminal blocks: These terminal blocks connect quickly and simply. The wires are only placed into the terminals, and spring-loaded clamps secure them there. They cannot be used with heavy or thick cables because they are not as secure as screw terminal blocks.

- Crimp terminal blocks: These terminal blocks are used with stranded wires and are known as crimp terminal blocks. Using a unique tool, the wires are crimped onto the terminals. Crimp terminal blocks can be used with a range of wire sizes and are highly secure.

- Barrier terminal blocks: These terminal blocks are used to isolate two or more circuits and are known as barrier terminal blocks. They have a base with several apertures, each of which has a barrier installed. The barriers are used to keep the wires from touching one another after they have been placed into the apertures.

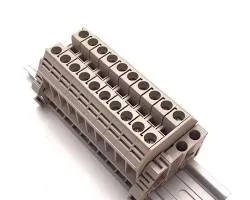

- DIN rail terminal blocks: These terminal blocks are intended to be installed on DIN rails. DIN rail terminal blocks. Electrical panels typically use DIN rails, which are universal mounting rails. Typically screw terminal blocks, DIN rail terminal blocks can also be push-in or crimp blocks.

How do terminal blocks work?

In order to connect wires in a safe and dependable manner, terminal blocks are used. The screws, spring-loaded clips, or crimps secure the wires once they have been put into the terminals. The terminals are then attached to a terminal strip by soldering, crimping, or screwing them.Choosing the right terminal block

There are a few things to take into account while selecting a terminal block, including:- The quantity of wires you must connect.

- The wires' diameter.

- Whether you require a screw, push-in, or crimp connection.

- How the terminal block will be used in its surroundings.

- The terminal block's price.

How to wire a terminal block?

Step 1: Disconnect the power.

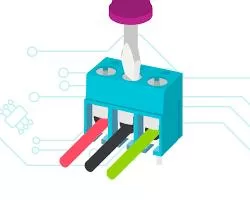

- For a screw-type terminal block, insert the wire into the hole and then tighten the screw.

- For a push-in type terminal block, simply insert the wire into the terminal until it clicks into place.

How to troubleshoot terminal blocks?

These procedures will help you solve a terminal block if you're having issues with it:- Verify the connections: Verify that the screws are secure and that the wires are placed all the way into the terminals.

- Cleaning the connections: If the connections are rusted, you can use a wire brush or a water-and-baking-soda solution to clean them.

- Replace the terminals: In the event that the terminals are broken, get new ones.

Wiring Precautions

- It must be assured that the power supply is turned off before operation during the wiring process and that no live operation is permitted. You can check with an electric pen or a multimeter if you are unsure whether the power source has been cut off. If there is a slip on a switch or terminal during wiring, it must be changed right away before usage because the risk of electric shock is greatly increased.

- Put the pvc threading pipe on when the power supply is connected. Set a hanging bracket at the corner of the piping during installation if it is a wire that has been inserted in the ceiling. Do not yank the wire at random. Do not attach the wire to the boom or keel without taking any fixing steps; instead, use a good fastened wire tube.

- It should be noticed that the wires shouldn't be too long in the switch box when they are being installed. Wires should not be placed into the switch for repair after wiring; instead, they should be sent into the conduit. Additionally, it is not advisable to position the host beneath a fixed plug because doing so could compromise the safety of household electricity.

Advantages of terminal blocks

- Versatility: A broad variety of wire sizes and types can be accommodated by terminal blocks, which are incredibly adaptable. They are excellent for a range of electrical and electronic applications since they can handle differing current and voltage ratings.

- Ease of installation: Installation is made simpler by the use of terminal blocks, which offer a handy method of connecting cables. For reliable connections, they frequently have screw terminals or spring-loaded clamps that firmly hold the wires in place.

- Modular design: Terminal blocks frequently have a modular form, making it simple to customize and expand electrical systems. The ability to add or remove more blocks as needed makes them flexible and responsive to shifting requirements.

- Space-saving: Terminal blocks aid in maximizing the use of available space in electrical enclosures or control panels. They eliminate clutter and enhance system efficiency by combining several cables into a single block.

- Enhanced safety: By establishing a dependable and secure connection, terminal blocks reduce the danger of exposed or loose wires. This lessens the possibility of electrical problems, short circuits, and possible dangers. Additionally, terminal blocks frequently contain insulating barriers that limit unintentional contact with live parts, improving worker safety.

- Easy troubleshooting: Maintenance and troubleshooting duties are made easier by terminal blocks. It is simpler to identify and isolate individual circuits or components by bundling together comparable wires. When doing repairs or system updates, this saves time and effort.

- Easy labeling and identification: Terminal blocks often contain enough room for identifying or labeling individual terminals. This makes wire connections easier to identify and record, which helps with system maintenance and troubleshooting.

- Compatibility with automation: Terminal blocks can be connected into automated systems, enabling effective management of wiring and connections. They simplify the automation process by being easily incorporated into programmable logic controllers (PLCs) or other control systems.

Disadvantages of terminal blocks

- Limited Current Capacity: Terminal blocks only have a particular amount of electrical current they can manage since they have a maximum current rating. If the current goes beyond this threshold, it may cause melting, fire risks, or even overheating. This restriction might not be advantageous in high-power applications with large current flows.

- Complexity of Wiring: Manual wiring for terminal blocks is frequently necessary, and this process can be time-consuming and prone to error. Especially when working with fine-gauge wires, connecting many wires to a single terminal can be difficult. The likelihood of misconnections, which result in improper connections or system failures, can rise with wiring complexity.

- Maintenance and troubleshooting: These tasks can be more difficult in systems that frequently use terminal blocks. It can take a while to locate and fix broken connections or terminals, especially when working with numerous terminal blocks. Downtime and maintenance expenses may rise as a result.

- Vibration and Shock Concerns: Terminal blocks are prone to vibration and shock, particularly in settings where the machinery is constantly moving or under mechanical stress. Vibrations can make wires or terminals loose, which results in sporadic or unsatisfactory connections.

- Limited Environmental Protection: Terminal blocks might not offer sufficient defense against environmental dangers like chemicals, moisture, or dust. These elements can cause corrosion, insulation failure, or short circuits in severe situations. To lessen these risks, further steps may be needed, such as enclosures or coverings.

FAQs about terminal blocks

What is the difference between a screw terminal block and a push-in terminal block? The way the wires are connected determines how a screw terminal block and a push-in terminal block differ from one another. The wires in a screw terminal block are screwed into the terminals. Wires are pushed into the terminals in a terminal block that uses push-in technology. Which type of terminal block is better? Your particular application will determine the optimal kind of terminal block for you. Push-in terminal blocks are less secure than screw terminal blocks, although screw terminal blocks can take longer to connect. While push-in terminal blocks are easier to connect, they offer less security. Where can I buy terminal blocks? Terminal blocks are available at most electrical supply stores. You can also buy them online.Populer Posts