Unveiling Fiber Optic Cables: Types, Installation, and Maintenance

May 07 2024

Inquiry

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

QUICK RFQ

ADD TO RFQ LIST

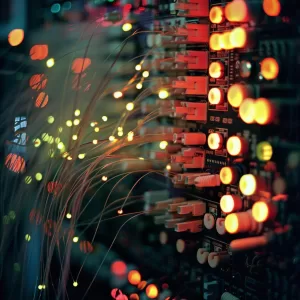

In this blog, we will delve into the fascinating world of fiber optic cables, empowering you with the knowledge you need.

What is Fiber Optic Cable?

What is Fiber Optic Cable Made of?

A fiber optic cable is typically composed of three basic components:- Core: The cable's core is this central strand, which might be constructed of glass or plastic. It carries the light pulses used to transfer data.

- Cladding: Cladding refers to a coating of glass or plastic that has a slightly lower refractive index than the core. The difference in refractive index helps confine light rays within the core, allowing for efficient transmission.

- Jacket: The outermost layer, usually made of PVC or other tough materials, protects the core and cladding from physical harm and environmental elements.

What are Two Characteristics of Fiber Optic Cable?

Fiber optic cables boast two significant advantages over traditional copper cables:- High Bandwidth: Fiber optic lines can transfer substantially more data than copper links. This results in significantly quicker internet connections, making it suitable for applications such as high-definition video streaming, online gaming, and massive file transfers.

- Low Signal Loss: Unlike copper connections, which suffer signal degradation over long distances, fiber optic cables transmit light pulses with little signal loss. This enables data transfer over long distances without the need for signal boosters.

What is Fiber Optic Cable Used for?

Fiber optic cables have a wide range of uses, which are constantly evolving. Here are some prominent applications:- Telecommunications: Fiber optic cables are the backbone of the modern internet, allowing high-speed data transfer over continents and long distances.

- Cable and Internet Service Providers (ISP): ISPs are progressively deploying fiber optic cables to provide ultra-fast internet access to homes and businesses.

- Data Centers: The ever-increasing demand for data storage and processing necessitates high bandwidth fiber optic cables within data centers.

- Medical Applications: Fiber optic cables are critical components of medical imaging equipment such as endoscopes, transmitting clear and detailed images for minimally invasive operations.

- Military and Defense: Secure communication and data transmission are critical during military operations. Fiber optic cables have a high bandwidth and are resistant to electromagnetic interference, making them excellent for various applications.

What Type of Fiber Optic Cable is Used for Internet?

There are two major types of fiber optic cables widely utilized for internet access:- Single-mode fiber: This type uses a single mode of light propagation, allowing for long-distance transmission with little signal loss. It is the recommended option for high-bandwidth applications such as backbone networks.

- Multi-mode fiber: This type allows for many modes of light propagation, has a larger core diameter for easy installation, but has shorter transmission distances than single-mode fiber. It is commonly utilized for short distances within buildings or campuses.

How do Fiber Optic Cables Work?

Total internal reflection is the notion that underpins fiber optic communication. Light pulses are delivered into the core of the fiber optic cable at an angle that surpasses the critical one. This allows the light to bounce off the core-cladding interface and go through the core, essentially trapping it inside the fiber. These light pulses denote the data being sent.Video related to how Fiber Optic Cables Work

How to Connect Fiber Optic Cable to Router?

It is impossible to connect a fiber optic connection directly to a standard home router. Fiber optic signals must be converted into electrical signals that routers can interpret using specialized equipment. This conversion is often performed at an optical network terminal (ONT) provided by your internet service provider (ISP). The ONT then connects to your router via an Ethernet wire.How to Install Fiber Optic Cable?

Due to the fragility of the core fibers, installing fiber optic cables can be a difficult task. For expert installation, it is usually advised that you hire a qualified fiber optic technician. However, if you're acquainted with certain DIY projects, here's a simple summary of fiber optic cable installation: Preparation:- Route planning: Plan the cable's path such that it avoids steep bends and any crushing dangers.

- Gathering tools: Cable cutters, strippers, cleaning materials (isopropyl alcohol), and, depending on the type of cable, specific connector equipment may be required.

- Cable Routing: Lay the cable carefully along the chosen route, taking care not to make tight bends.

- Cable Preparation: Using the appropriate tools, remove the outer jacket and cladding to reveal the core. Be extremely careful not to scratch or damage the core fiber.

- Cleaning: To remove dust or impurities from the core fiber, use lint-free wipes and isopropyl alcohol.

- Termination (optional): If you connect the cable directly to the equipment, you may need to terminate the fiber with specific connections such as SC or LC connectors using the proper tools. Consult a specialist about proper termination techniques.

- Securing the cable: Use cable ties or other suitable techniques to secure the cable at regular intervals throughout its path, preventing strain or movement.

How to Test Fiber Optic Cable?

There are two primary ways to inspect fiber optic cables:- Visual inspection: Examine the cable for evident damage to the outside jacket or connections.

- Light source and power meter: A light source sends light pulses across the cable, while a power meter at the other end measures the received light intensity. This helps to spot any substantial signal loss or cable breaks.

How to Fix Fiber Optic Cable?

Unfortunately, due to the fragile nature of the fibers, replacing a broken fiber optic cable core is frequently impossible. However, based on the damage:- Minor jacket damage: If the outer jacket is damaged but the core appears to be intact, you may be able to repair it with specialist heat shrink tubing.

- Connector issues: If the problem is with the connector, replacing it may be doable; however, consult a professional for suitable ways.

How to Clean Fiber Optic Cable?

Fiber optic cables rarely require substantial cleaning. However, accumulating dust or dirt on the connector ends can interfere with signal transmission. How to Clean Fiber Optic Cable Connectors:- Gather supplies: Isopropyl alcohol, lint-free cloths, and compressed air (can).

- Power down: Before cleaning, turn off any connected equipment.

- Disconnect the cable: Carefully detach the cord from the apparatus.

- Cleaning: Use a lint-free cloth wet with isopropyl alcohol to carefully clean the connector ferrule (the cylindrical end). Avoid contacting the bare fiber tip.

- Compressed air (optional): Use compressed air to remove any dust particles that may be trapped in the connector.

How to Check Fiber Optic Cable?

Regularly inspecting your fiber optic cable for visible damage to the outside jacket or connectors is a good idea. You may also monitor the speed of your internet connection. A considerable decline in speed may indicate a problem with the fiber optic cable. However, for more thorough testing and troubleshooting, it is best to visit a certified fiber optic professional.How Deep is Fiber Optic Cable Buried?

The burial depth of fiber optic cables can vary based on numerous factors, including- Terrain: In regions with uneven terrain or potential hazards such as rocks or tree roots, cables may be buried deeper for safety.

- Right-of-way regulations: Local regulations controlling underground utility installations may include minimum burial depths.

- Application: The depth of long-distance underground cables between cities can range from 3 to 6 feet (1 to 2 meters), or even deeper. Shorter underground runs within a property may be shallower, but still deep enough to prevent inadvertent harm.

Where to Buy Fiber Optic Cable?

Because of their specialist nature, fiber optic cables are rarely available at traditional consumer electronics retailers. Here are several sites to buy them:- Telecom Equipment Distributors: Companies that specialize in telecommunications equipment frequently sell fiber optic cables of various lengths and types.

- Online Retailers: Several internet stores provide fiber optic cables; however, be cautious and ensure they are reliable suppliers selling high-quality cables.

- Cable type: Single-mode or multi-mode, depending on your needs.

- Cable length: Select the proper length to avoid extra slack or cable splicing.

- Connector type: Check that the connectors on the cable are compatible with your equipment.

- Jacket type: Choose a jacket material that is appropriate for the cable's setting (indoor, outdoor, etc.).

Conclusion

Fiber optic cables are transforming data transmission by providing unprecedented speed, reliability, and capacity. You may use this sophisticated technology for your house or business by understanding how it works, what varieties are available, and how to maintain it. Remember that for important installations or difficult troubleshooting, you should always seek a certified fiber optic specialist. What is Fiber Optic CableWhat is Fiber Optic Cable Made ofWhat are Two Characteristics of Fiber Optic CableWhat is Fiber Optic Cable Used forWhat Type of Fiber Optic Cable is Used for InternetHow do Fiber Optic Cables WorkVideo related to How do Fiber Optic Cables WorkHow to Connect Fiber Optic Cable to RouterHow to Install Fiber Optic CableHow to Test Fiber Optic CableHow to Fix Fiber Optic CableHow to Clean Fiber Optic CableHow to Check Fiber Optic CableHow Deep is Fiber Optic Cable BuriedWhere to Buy Fiber Optic CableConclusion

Related Articles

- ·Stratix 10 VS Stratix V: Which FPGA is Right for Your Next Project?

- ·Intel Xeon Platinum 8454H vs AMD EPYC: Which Reigns Supreme?

- ·A Deep Dive into the AMD EPYC 4564P Processor

- ·MSP430F5438A vs MSP430F5529: A Detailed Analysis of Their Capabilities

- ·Comparing MSP430F6659 and MSP430F5419A: Which One is Right for Your Project?

- ·Exploring the Features of MSP430F5529 and MSP430F5638 Microcontrollers

- ·Demystifying 20 Microcontroller Projects for Beginners

- ·Unveiling the Ultimate Guide to Microcontroller Programming

- ·4680 Battery: Unveiling the Power Potential of the Next-Gen Cell

- ·Exploring the Case Studies on Arduino Applications

Populer Posts

DMVA2ZCED

Texas Instruments

UPD77210F1-DA2-A

Renesas Electronics America Inc

CS48LV41-CWZR

Cirrus Logic Inc.

ADSP-3201JG

Analog Devices Inc.

ADSP-BF561SKBCZ-6V

Analog Devices Inc.

ADSP-2171KST-133

Analog Devices Inc.

TMS320C6745DPTP4

Texas Instruments

ADSP-21593KBPZ10

Analog Devices Inc.

TMS320BC51PZ80

Texas Instruments

TMS320C6747DZKB3

Texas Instruments

CA3194E

Harris Corporation

ADSP-BF533SBB500

Analog Devices Inc.