In this blog, we will delve into the world of RJ45 connectors, exploring their history, functions, applications, installation tips, and potential d...

View detailsUnderstanding Thyristors: How They Work and Where They’re Used

Thyristors are essential parts of contemporary power systems and electronics, and they are important for regulating high-power circuits. We will examine the internal workings of thyristors, their uses, and the factors that contribute to their ongoing importance across a range of industries in this blog.

From understanding the thyristor symbol to exploring their applications in high voltage systems and power control, this blog aims to provide a thorough understanding of thyristors and their significance in today's technological landscape.

What Are Thyristors?

Thyristors, often referred to as silicon-controlled rectifiers (SCRs), are semiconductor devices that act as bistable switches, conducting current only after they are triggered. Composed of three P-N junctions, they are made up of four layers that alternate between N and P-type materials. An anode, cathode, and gate represent the three terminals of a thyristor, and this is the basic symbol for it. An increased current can flow from the anode to the cathode by turning on the thyristor when a tiny current is applied to the gate terminal. For applications requiring high current and voltage control, thyristors are perfect due to this special feature.

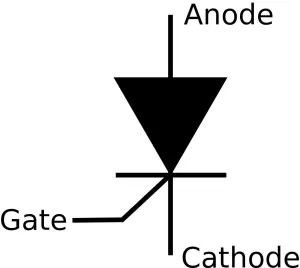

Thyristor Symbol

In circuit diagrams and technical documentation, the thyristor symbol—a pictorial depiction of its internal structure—is essential. With an extra control terminal called the gate, it looks like a diode. The direction of current flow is indicated by the anode, which is an arrow pointing outward, and the cathode, which is a line that is perpendicular to it. The control terminal that initiates the thyristor's switching behavior is represented by the gate, which is a vertical line that crosses the anode and cathode.

Video related to Thyristors

How Thyristors work?

- Initial State: There is no current flow because the thyristor is in the open switch state.

- Triggering: The p-n junctions break down and the thyristor becomes conductive when a current pulse is applied to the gate.

- Latching Mechanism: Because of the latching mechanism, the thyristor keeps conducting even after the gate current is cut off.

- Turning Off: Reducing the current passing through a thyristor below the holding current is how it is turned off.

How Thyristors are Made?

The manufacturing of thyristors involves a series of intricate steps, including:

- Crystal Growth: A large single-crystal ingot is formed by subjecting high-purity silicon to a process known as Czochralski pulling.

- Wafer Slicing: Next, the silicon ingot is cut into thin wafers, each of which acts as the foundation for a separate thyristor device.

- Doping and Diffusion: To produce the essential P-N junctions that are the cornerstone of the thyristor's functioning, impurities like phosphorus and boron are added to the silicon wafers. This process, called doping, is accomplished by a number of methods, such as diffusion and ion implantation.

- Metallization: To make electrical connections to the thyristor's terminals easier, contact regions—typically composed of aluminum or molybdenum—are deposited onto the wafer.

- Encapsulation: To guarantee the processed wafers' longevity and dependability under varied operating circumstances, they are subsequently encapsulated in protective containers made of plastic or ceramic.

- Testing and Evaluation: Strict testing protocols are used to confirm the electrical properties and functionality of the thyristors that are produced.

What are Thyristors Made of?

Semiconductor materials, like silicon, are the main component of thyristors. During the manufacturing process, these materials are transformed into P-N junctions, which are essential for the device's functionality. The electrical characteristics of the thyristor are largely dependent on how these materials are doped with particular impurities. Subsequently, the assembled structure is housed in a weatherproof enclosure to create a thyristor module, guaranteeing its robustness and dependability under diverse operational circumstances.

Thyristors vs Transistors

Although they are both semiconductor devices, thyristors and transistors operate differently and have different applications. Because of their tendency to latch, thyristors need an outside signal to switch from the conducting state to the non-conducting state. On the other hand, transistors that are in the amplification mode can control current flow with a small control signal.

Here's a table summarizing the key differences between thyristors and transistors:

| Feature | Thyristor | Transistor |

| Switching behavior | Latching | Non-latching |

| Current control | High-power switching | Signal amplification and current regulation |

| Turn-off mechanism | Requires specific techniques | Turn off with minimal control signal |

| Applications | Motor control, power transmission, heating systems, lighting control | Amplifiers, logic gates, signal processing |

Where can Thyristor be Used?

- Power Control: Power control applications like motor drives, lighting control, heating control, and power supplies frequently use thyristors. They are appropriate for managing heavy electrical loads because they can withstand high voltages and currents.

- AC Power Switching: Thyristors are utilized in AC power switching applications, such as solid-state relays and the regulation of AC power to machinery and equipment in industries.

- Voltage Regulation: To maintain a stable output voltage, thyristors are used in voltage regulation circuits, such as voltage regulators and voltage stabilizers.

- Rectification: In rectifier circuits, thyristors are used to convert AC power to DC power for use in DC motor drives, welding equipment, and battery charging, among other applications.

- Inverters: Thyristors are essential parts of inverters, which are devices that change DC power into AC power for use in solar power systems and uninterruptible power supplies (UPS).

- High-Voltage Direct Current (HVDC) Transmission: For effective long-distance electrical power transmission, thyristors are used in HVDC transmission systems.

- Induction Heating: Thyristors are used in melting, forging, and metal heat treatment processes in induction heating systems.

Are Thyristors Still Used and Why?

In many industrial and commercial applications, thyristors are still indispensable despite the advances in semiconductor technology. They are indispensable in power electronics due to their robustness, dependability, and capacity to handle high power levels. Furthermore, thyristors' special qualities—like their resistance to high temperatures and voltage swings—help explain why they are still useful in harsh settings.

Are Thyristors ESD Sensitive?

Since thyristors are typically susceptible to electrostatic discharge (ESD), handling and protection during the manufacturing and assembly processes must be taken carefully. Appropriate ESD protection techniques, like shielding and grounding, are used to reduce the possibility of ESD damage. Furthermore, thyristors can be disabled by lowering the anode current below a holding current threshold. This cut-off mechanism is essential for managing thyristor operation and averting inadvertent conduction.

Which Thyristor is the Most Widely Used?

The silicon-controlled rectifier (SCR), with its high current handling capacity and resilience, is the most popular type of thyristor among the other varieties. In industrial heating systems, where accurate power control is crucial to preserving ideal operating conditions, SCRs are widely used. Their capacity to manage elevated currents and voltages renders them perfect for uses necessitating dependable and effective power regulation.

Conclusion

In conclusion, thyristors are essential components of contemporary electronics and power systems because of their unmatched capacity for high-power control and regulation. Thyristors are still essential parts of today's technological environment because of their distinct working principles and wide range of uses in the commercial, industrial, and transportation sectors. Thyristors are predicted to remain relevant as long as there is a need for effective power management and high-performance electronics, which will spur additional advancements in power electronics and system integration.

Ella

Ella is a skilled embedded systems engineer with experience in PCB design and microcontroller programming. She is committed to following the most recent developments in the field and is constantly seeking for ways to apply them to her work.

WEW ALL POSTS BYElla-

Understanding RJ45 Connectors: Applications and Installation Tips 97

-

Diode Basis: Symbol, Types and Applications 386

Diodes are essential components in electronics, serving important functions such as rectification, modulation, regulation, and protection. They com...

View details -

Unraveling the Mystery of Oscillators 112

In this blog, we will delve into the world of oscillators, unraveling their mysteries and exploring their applications in the intricate world of el...

View details -

SAR ADC-A Specific Type of ADC 369

A Successive Approximation Register (SAR) ADC is a type of analog-to-digital converter that uses a binary search algorithm to convert analog signal...

View details -

A/D Converter: Basic Principle and Types 373

The A/D converter plays a crucial role in various applications, including telecommunications, audio processing, sensor data acquisition, and more. ...

View details -

DSP vs. Microprocessor: What is the difference between them? 566

Digital signal processors (DSPs) and microprocessors are two different categories of processors that are used to process and operate electronic dev...

View details

Ampheo Electronics

Ampheo Electronics