IGBT in Power Electronics: A Cornerstone of Modern Power Electronics

November 09 2023

Inquiry

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

QUICK RFQ

ADD TO RFQ LIST

The Insulated Gate Bipolar Transistor (IGBT) is a key component in power electronics that has significantly transformed a number of sectors. In this blog, we aim to provide a comprehensive understanding of IGBT, its applications, advantages, and working principles. Whether you're an electronics enthusiast or a professional seeking in-depth knowledge, this guide will equip you with valuable insights into the world of IGBT.

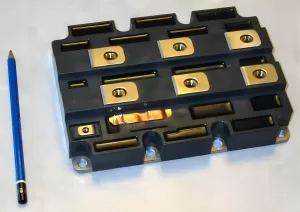

What is IGBT in electronics?

Insulated-Gate Bipolar Transistor, an apt acronym for its distinct construction and functioning, is what IGBT stands for. IGBTs combine the voltage-controlled gate of a MOSFET with the current-handling capabilities of a bipolar transistor, in contrast to traditional Mosfets (Metal-Oxide-Semiconductor Field-Effect Transistors), which only rely on voltage control. IGBTs are perfect for high-voltage and high-current applications because of their hybrid construction, which gives them remarkable power-switching capabilities.

When was IGBT invented?

Under the direction of Dr. B. Jayant Baliga, a group of researchers at General Electric (GE) invented the IGBT (Insulated Gate Bipolar Transistor) in 1983. The IGBT, which changed the field of power electronics technology, is credited to Dr. Baliga. The creation of the IGBT was a major advancement since it brought together the benefits of bipolar junction transistors and MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), enabling effective power switching in a variety of applications. Since its creation, the IGBT has developed into a crucial part of power electronic systems, advancing a variety of sectors including industrial automation, renewable energy, and electric cars.Why IGBT is Popular Nowadays?

IGBTs have gained widespread popularity due to several factors:- High performance: IGBTs have quick switching times, good efficiency, and the capacity to handle large voltages and currents.

- Reliability: IGBTs can tolerate challenging operating circumstances and are comparatively sturdy.

- Cost-effectiveness: When weighed against alternative power semiconductor technologies, IGBTs are comparatively inexpensive.

- Versatility: IGBTs are a flexible option for power electronics design because of their extensive range of applications.

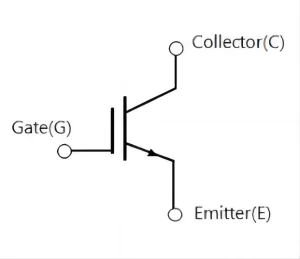

Symbol for IGBT

- Gate Layer: The gate layer is made of insulating material, such as silicon dioxide, and is used to control the flow of current between the collector and emitter.

- P-Substrate Layer: The p-substrate layer forms the base of the IGBT structure and provides a path for current flow.

- N-Drift Layer: The n-drift layer is located between the gate layer and the p-substrate layer and controls the flow of current from the collector to the emitter.

What does IGBT do?

The IGBT (Insulated Gate Bipolar Transistor) is a power semiconductor device that serves as a switch in electronic circuits. It combines the advantages of MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) and bipolar junction transistors, making it suitable for high voltage and high current applications. Here are some key functions and capabilities of IGBTs:- Power Switching: The primary function of an IGBT is to control the flow of electrical power in a circuit. It can handle high voltage and current levels, making it ideal for applications that require efficient power switching, such as motor drives, inverters, and converters.

- Voltage and Current Amplification: Similar to a bipolar junction transistor, the IGBT can amplify both voltage and current signals. This capability allows it to control large amounts of power with a small input signal.

- Fast Switching Speed: IGBTs can switch on and off rapidly, enabling high-frequency operation in applications such as switch-mode power supplies and high-frequency induction heating.

- High Efficiency: IGBTs have low conduction losses and low switching losses, resulting in high overall efficiency in power electronic systems. This efficiency is crucial for applications that require energy conservation and reduced heat dissipation.

- Thermal Management: IGBTs generate heat during operation, and proper thermal management is essential to ensure their reliability. Heat sinks, cooling systems, and thermal design considerations are employed to maintain optimal operating temperatures.

- Protection Features: IGBTs often incorporate protection features such as overvoltage protection, overcurrent protection, and temperature monitoring. These features help safeguard the device and the overall system from potential damage or failure.

Video related to IGBT

How to Check an IGBT with a Multimeter?

- Set the Multimeter: Turn on the multimeter and select the continuity or diode test modes (a sound wave or a diode symbol is typically used to show continuity).

- Identify the IGBT Pins: How to Find the IGBT Pins The collector (C), the emitter (E), and the gate (G) are the three pins that make up the IGBT. For information on the pin configuration of the particular IGBT model, consult the datasheet or the manufacturer's documentation.

- Test the Collector-Emitter Junction: Put the red positive lead of the multimeter on the IGBT's collector pin (C) and the black negative lead on its emitter pin (E). A voltage drop of around 0.6 to 0.7 volts in the forward bias direction should be shown by the multimeter if the IGBT is operating properly. An open circuit (OL) or noticeably higher voltage readings suggest an IGBT malfunction.

- Test the Gate-Emitter Junction: Place the multimeter's positive lead on the emitter pin (E) and negative lead on the gate pin (G). The multimeter should provide an open circuit (OL) or an extremely high resistance measurement during this test, indicating that the emitter and gate should not be connected. A malfunctioning IGBT is suggested if the multimeter displays low resistance or a short circuit.

- Reverse Polarity Test: To perform a reverse polarity test, turn the multimeter's leads so that the positive lead is on the emitter pin (E) and the negative lead is on the collector pin (C). Indicating that there shouldn't be any continuity in the reverse bias direction, the multimeter should show an open circuit (OL) or an extremely high resistance value. The multimeter indicates a possible malfunctioning IGBT if it displays low resistance or a short circuit.

IGBT vs Mosfet

IGBTs are a viable option for applications that need high power levels and minimal switching losses because of their reputation for having great switching speed and efficiency. They are appropriate for uses like industrial motors and electric cars since they can manage high currents. In contrast, MOSFETs are renowned for having low on-state resistance and low gate voltage. For low-power and efficiency-sensitive applications, in particular, where switching speed is not as crucial, this makes them an excellent option. Here is a table summarizing the key differences between IGBTs and MOSFETs:| Feature | IGBT | MOSFET |

| Switching speed | High | Low |

| Efficiency | High | Low |

| Current handling | High | Low |

| Gate voltage | High | Low |

| On-state resistance | High | Low |

IGBT vs SiC

For power electronics, IGBTs are the industry standard because of their well-established technology, affordable price, and track record of reliability. They are perfect for applications such as industrial motors, renewable energy inverters, and electric cars because they have rapid switching speeds, efficient power conversion, and the capacity to manage enormous currents. Future power electronics semiconductors, known as silicon carbide (SiC) devices, have several benefits over indium-galvanized graphene transistors (IGBTs). SiC transistors can function at higher temperatures, endure higher voltages, and switch considerably faster than silicon transistors because they have a larger bandgap than silicon. This qualifies them for use in high-voltage direct current (HVDC) transmission, high-power PFC converters, and electric car battery chargers—applications where efficiency, power density, and thermal management are essential. Here's a table summarizing the key differences between IGBTs and SiC transistors:| Feature | IGBT | SiC Transistor |

| Switching speed | High | Much faster |

| Efficiency | High | Higher |

| Power density | High | Much higher |

| Operating temperature | Up to 125°C | Up to 250°C |

| Voltage handling | High | Much higher |

| Cost | Lower | Higher |

How IGBT Works?

To understand how an IGBT works, let's delve into its internal structure and operation:- Structure: The emitter, collector, and gate are the three primary layers of an IGBT. The layer of insulation known as the gate regulates the flow of current between the emitter and the collector. While the collector is a weakly doped zone that gathers the electrons, the emitter is a substantially doped region that injects electrons into the channel.

- Operation: The gate of an IGBT is voltage-applied. Electrons from the emitter are drawn into the channel by an electric field produced by a positive voltage applied to the gate. As a result, the channel becomes more conductible, and current can go from the emitter to the collector.

- Voltage Control: The IGBT's current flow is regulated by the gate voltage. It is possible to accurately control the current flow by varying the gate voltage. IGBTs are therefore perfect for applications like power inverters and motor drives that need precise current regulation.

When to Use IGBT?

IGBTs are suitable for a wide range of applications that require high power handling, fast switching speeds, and efficient operation. Some common applications include:- Motor drives: IGBTs are used in motor drives to regulate the torque and speed of both AC and DC motors.

- Power inverters: To convert DC power to AC power, power inverters use IGBTs.

- Switching power supplies: To convert AC power to DC power, switching power supplies require IGBTs.

- Induction heating: To provide heat for a range of manufacturing and industrial operations, induction heating systems employ IGBTs.

- Uninterruptible power supplies (UPS): IGBTs are utilized in UPS systems, which are designed to supply backup power in the event of an outage.

What can cause an IGBT to fail?

- Electrical Overstress: When an IGBT is subjected to high current, voltage, or power management that is above the design limitations of the device, electrical stress can result in IGBT failure. The IGBT may become permanently damaged as a result of these circumstances, rendering it non-functional.

- Thermal Overstress: In inefficient general-purpose transistors (IGBTs), high currents, switching losses, or insufficient cooling can cause excessive heat buildup. As a result, the semiconductor material may sustain irreversible damage from the IGBT's junction temperature rising above its maximum permitted value.

- Manufacturing Defects: During the intricate semiconductor device manufacturing process, IGBTs may have manufacturing errors. These flaws, which could cause the IGBT to fail prematurely, could appear as electrical shorts, material impurities, or structural flaws.

Where to Buy IGBT?

IGBTs can be purchased from various reputable electronics distributors and manufacturers. Some well-known suppliers of IGBTs include:- Infineon Technologies

- ABB Semiconductors

- Mitsubishi Electric

- STMicroelectronics

- Texas Instruments

Conclusion

IGBTs have transformed the world of power electronics by making a variety of high-power applications possible that were not previously feasible or feasible. Because of their outstanding power-switching capabilities, which come from their unique mix of bipolar structure and voltage-controlled gate, they are an essential component in many different sectors. Engineers and hobbyists alike need to comprehend the subtleties of IGBTs to design and construct dependable, strong, and effective electronic systems. IGBTs are anticipated to become even more significant in influencing the direction of electronics as time goes on and power requirements rise.Related Articles

- ·Stratix 10 VS Stratix V: Which FPGA is Right for Your Next Project?

- ·Intel Xeon Platinum 8454H vs AMD EPYC: Which Reigns Supreme?

- ·A Deep Dive into the AMD EPYC 4564P Processor

- ·MSP430F5438A vs MSP430F5529: A Detailed Analysis of Their Capabilities

- ·Comparing MSP430F6659 and MSP430F5419A: Which One is Right for Your Project?

- ·Exploring the Features of MSP430F5529 and MSP430F5638 Microcontrollers

- ·Demystifying 20 Microcontroller Projects for Beginners

- ·Unveiling the Ultimate Guide to Microcontroller Programming

- ·4680 Battery: Unveiling the Power Potential of the Next-Gen Cell

- ·Exploring the Case Studies on Arduino Applications

Populer Posts

ATSAMD21E15B-AF

Microchip Technology

MB9AF344NBPQC-G-JNE2

Infineon Technologies

R5F5671EDGLJ#20

Renesas Electronics America Inc

R7F7010453AFP#KA2

Renesas Electronics Corporation

SPC5646BAMLU1R

NXP Semiconductors

EFM32WG990F64-B-BGA112R

Silicon Labs

R5F101LGAFB#70

Renesas Electronics Corporation

PIC24F08KM202-I/ML

Microchip Technology

STM8AL3148TAY

STMicroelectronics

W78E365A40PL

Nuvoton Technology Corporation

S912ZVC64F0VLF

NXP Semiconductors

STM8AL3136UCY

STMicroelectronics