ASIC in the Digital Age: Adapting to Technological Shifts

January 09 2024

Inquiry

Global electronic component supplier AMPHEO PTY LTD: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

QUICK RFQ

ADD TO RFQ LIST

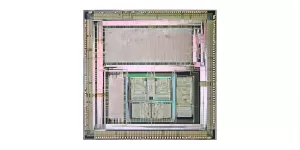

In this blog, we will delve into what ASIC stands for, explore how ASIC works, decipher the intricacies of ASIC design, and uncover the strategic locations where ASICs are integrated into the digital infrastructure, and so on.

What ASIC Stands For?

What is ASIC Design?

ASIC design is the intricate process of developing an integrated circuit (IC) specifically fitted to a given application. ASICs are painstakingly designed for a particular purpose, as opposed to general-purpose chips like CPUs, which are mass-produced. This allows ASICs to perform, function, and cost-effectively perform better for their intended tasks. Here's a breakdown of the key steps involved in ASIC design:- Conceptualization and Specification:

- Determine the particular application and the features that are needed for it.

- Specify the power consumption, cost limitations, and performance criteria.

- Select the ASIC's suitable architecture and technology (such as CMOS or FinFET).

- Design and Implementation:

- Utilizing Hardware Description Languages (HDLs) such as VHDL or Verilog, develop the logic design.

- To confirm the design's functionality and spot any potential flaws, simulate it.

- Place and route the circuit parts on the chip in the physical layout.

- Performance, power consumption, and area use should all be optimized in the design.

- Verification and Validation:

- Conduct thorough tests and simulations to make sure the ASIC satisfies all functional and performance requirements.

- Make sure the layout satisfies production requirements by doing a physical verification.

- Before committing to manufacture, evaluate the design's functionality using a prototype made of Field-Programmable Gate Arrays (FPGAs).

- Fabrication and Testing:

- Send the blueprint for silicon wafer production to a semiconductor foundry.

- Make sure the manufactured chips are thoroughly tested to find and fix any manufacturing flaws.

- Packaging and System Integration:

- Assemble the chips in appropriate cases to ensure their safety and seamless incorporation into the finished item.

- Assemble the entire system by integrating the ASICs with other parts (such as sensors and memory).

Video related to ASIC

How ASIC Works?

ASICs work in electrical devices by carrying out predetermined tasks. ASICs use specially constructed circuitry to provide optimum performance for a variety of functions, including data encryption and signal processing. Their specialized design makes it possible for them to be seamlessly integrated into electrical systems, improving efficiency and functionality all around.Where is ASIC Located?

ASICs are carefully incorporated into several digital systems and gadgets that are used in a broad range of sectors and applications. They are found everywhere, supporting vital operations in industrial machinery, consumer electronics, telecommunications infrastructure, automobile technology, and other fields. ASICs are positioned strategically to maximize performance and usefulness in a variety of applications, from smartphones and Internet of Things devices to cutting-edge medical equipment and aerospace technologies.The Evolution of ASICs in the Digital Age

In the digital era, Application-Specific Integrated Circuits (ASICs) have seen a tremendous and revolutionary evolution. Technology has advanced significantly thanks in large part to ASICs, which have made it possible to create intricate electrical systems. Here's an overview of the evolution of ASICs in the digital age:- Early Adoption: ASICs were mainly utilized in specialized applications where the achievement of particular functionality required the usage of specially built integrated circuits in the early days of digital technology. Due to their high development and manufacturing costs, these early ASICs were only useful in high-volume applications.

- Advancements in Semiconductor Technology: The cost of creating and designing ASICs dropped as semiconductor manufacturing techniques improved. ASICs were consequently used in more industrial systems, consumer electronics, and telecommunications equipment.

- Customization and Optimization: By enabling manufacturers to design extremely effective and specific hardware for their goods, ASICs made it possible to customize and optimize electronic systems. Electronic devices became smaller, more power-efficient, and performed better as a result.

- Integration and Miniaturization: As ASIC technology developed, there was a notable rise in both integration and miniaturization. Modern ASICs enable the construction of more powerful and compact electronic devices by combining complicated digital and analog functionalities onto a single chip.

- Application in Emerging Technologies: Artificial intelligence, machine learning, mining cryptocurrency, and high-performance computing are just a few of the developing areas where ASICs are being used. ASICs are ideally suited to deliver the specific hardware acceleration that these applications require.

- Role in IoT and Edge Computing: The use of ASICs has increased as a result of the growth of edge computing and the Internet of Things. ASICs have shown to be crucial in helping these technologies satisfy their hardware requirements for processing data at the edge of networks, which call for effective and specialized hardware.

- Challenges and Opportunities: Although ASICs have a lot to offer in terms of performance, there are certain drawbacks, including design complexity, time to market, and non-recurring engineering expenditures. Nonetheless, these issues are still being addressed by developments in semiconductor manufacturing techniques, IP reuse, and design tools.

FPGA vs ASIC

Although they are both integrated circuit types, Field-Programmable Gate Arrays (FPGAs) and Application-Specific Integrated Circuits (ASICs) serve various functions and have unique features. Here's a comparison of FPGA vs ASIC: Flexibility:- FPGA: FPGAs are renowned for being reprogrammable, which enables customers to alter the hardware after it has been manufactured. Because of their adaptability, FPGAs are good for fast development, prototyping, and applications where design changes happen often.

- ASIC: Application-specific and purpose-specific, ASICs are made for a particular use. Their functionality is set once they are built and cannot be altered, providing excellent performance for a particular purpose.

- FPGA: Because FPGAs can be reprogrammed, they enable quick prototyping and development, which reduces time to market. They are therefore perfect for uses where time-to-market is crucial.

- ASIC: Because of the design, verification, and manufacturing procedures, developing ASICs usually takes longer. Once implemented, ASICs can provide better performance and less power usage.

- FPGA: When design changes occur frequently or production volumes are low to medium, FPGAs may prove to be more economical. They might, however, cost more per unit in high-volume manufacturing than ASICs.

- ASIC: Due to lower unit prices and possibly lower power consumption, ASIC development can be more cost-effective for high-volume production even though it entails greater upfront costs.

- FPGA: FPGAs are capable of optimizing performance for particular workloads and provide good performance overall. They might not, however, perform as well as ASICs in extremely specialized applications.

- ASIC: Specifically engineered to fulfill certain functions, ASICs provide optimal performance and efficiency for the given use case. For specific jobs, they can exceed FPGAs in terms of speed and power efficiency.

- FPGA: Because of their general-purpose architecture and programmability, FPGAs generally use more power than ASICs.

- ASIC: Compared to FPGAs for the same application, ASICs require less power because they are designed for particular jobs.

Conclusion

In conclusion, ASICs are at the vanguard of technological innovation, facilitating the landscape's constant change in the digital age. Future developments in electronics and digital systems are largely influenced by ASICs, from their specialized design to their essential role in developing technologies. ASICs will continue to be a mainstay of innovation as sectors and applications change, adjusting to technological advancements and spearheading the subsequent wave of digital revolution.Related Articles

- ·Stratix 10 VS Stratix V: Which FPGA is Right for Your Next Project?

- ·Intel Xeon Platinum 8454H vs AMD EPYC: Which Reigns Supreme?

- ·A Deep Dive into the AMD EPYC 4564P Processor

- ·MSP430F5438A vs MSP430F5529: A Detailed Analysis of Their Capabilities

- ·Comparing MSP430F6659 and MSP430F5419A: Which One is Right for Your Project?

- ·Exploring the Features of MSP430F5529 and MSP430F5638 Microcontrollers

- ·Demystifying 20 Microcontroller Projects for Beginners

- ·Unveiling the Ultimate Guide to Microcontroller Programming

- ·4680 Battery: Unveiling the Power Potential of the Next-Gen Cell

- ·Exploring the Case Studies on Arduino Applications

Populer Posts

ADSP-BF523KBCZ-6C2

Analog Devices Inc.

TMS320C6678AXCYPA

Texas Instruments

TNETV2510GGW

Texas Instruments

TMS320C6205ZWT200

Texas Instruments

66AK2G12ABYA60E

Texas Instruments

TNETV1644ZDU6

Texas Instruments

TMS320LC50PQ57

Texas Instruments

ADSST-2185LKST-133

Analog Devices Inc.

SAF7771EL/200Z130K

NXP Semiconductors

ADSP-2186MBSTZ266R

Analog Devices Inc.

ADSP-21261SKBCZ150

Analog Devices Inc.

MSC8156VT1000B

Freescale Semiconductor, Inc. (NXP Semiconductors)